Aluminum Foil Snack Box Automatic Power Punch Press /Sheet Metal Stamping Machine

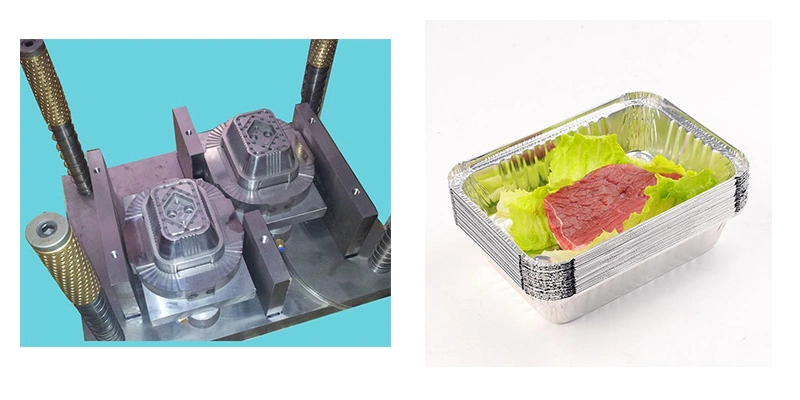

Stamping die display

Product Introduction

Hangyu company has specialized in the punching press working line machines and other metal sheet fabrication machines making field nearly 30 years, We have lots of experience on the aluminum foil food container machines making,we export our machines to all the worldwide market and have the best response from customers.We can provide you different capacity machine,etc:45ton,63ton,80ton,100ton.And different molds for various food container,which can made with one cavity,two cavities,and more.We can also customize the machine by requirement and offer you our best quality machine and the after-sale service.

Components of this production line:

1. Auto-feeder with lubrication system

2. Punching machine

3. Electrical control system

4. Stamping mold

Production Steps:

Lubricating material------Feeding material------Punching by the press------Collecting product

Certifications:

Our Advantage:

1. Our guarantee time is one year, if any component is damaged during guarantee time, we can send the component to the customer by DHL, TNT freely.

2. Our factory can send our engineer to the customer's factory install, commission and training freely. The customer provide the double trip tickets, food and accommodation for our engineer. The customer also can send the engineer to our factory to learn the operation and maintains freely.

3. Our factory provide the service for the customer forever, if the customer need operation help, can contact us by MSN, Skype, Email and Telephone at any time, we provide 24 hours on-line service. Our factory also will make DVD to show the operation steps for the customer.

Main features:

1.This production line can work automatically.Worker control and regulate this production line through electric control equipment.There is an auto-lubricator on the feeder, which can lubricate aluminium foil automatically.The foil feeder provides the supply of right quantity and length of aluminium foil, and it is controlled by servo system in SEIMENS, which assure a high-precision step.

2.We can also design and manufacture according to customer's requirment and customer's target pric

Packing & Delivery

FAQ:

1. Auto-feeder with lubrication system

2. Punching machine

3. Electrical control system

4. Stamping mold

Production Steps:

Lubricating material------Feeding material------Punching by the press------Collecting product

Certifications:

Our Advantage:

1. Our guarantee time is one year, if any component is damaged during guarantee time, we can send the component to the customer by DHL, TNT freely.

2. Our factory can send our engineer to the customer's factory install, commission and training freely. The customer provide the double trip tickets, food and accommodation for our engineer. The customer also can send the engineer to our factory to learn the operation and maintains freely.

3. Our factory provide the service for the customer forever, if the customer need operation help, can contact us by MSN, Skype, Email and Telephone at any time, we provide 24 hours on-line service. Our factory also will make DVD to show the operation steps for the customer.

Main features:

1.This production line can work automatically.Worker control and regulate this production line through electric control equipment.There is an auto-lubricator on the feeder, which can lubricate aluminium foil automatically.The foil feeder provides the supply of right quantity and length of aluminium foil, and it is controlled by servo system in SEIMENS, which assure a high-precision step.

2.We can also design and manufacture according to customer's requirment and customer's target pric

Packing & Delivery

| Packaging | Steel Pallet |

| Packaging Details | The normal package is wooden box. If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |